Engines

Powerful - Small - Light - Low in Vibrations

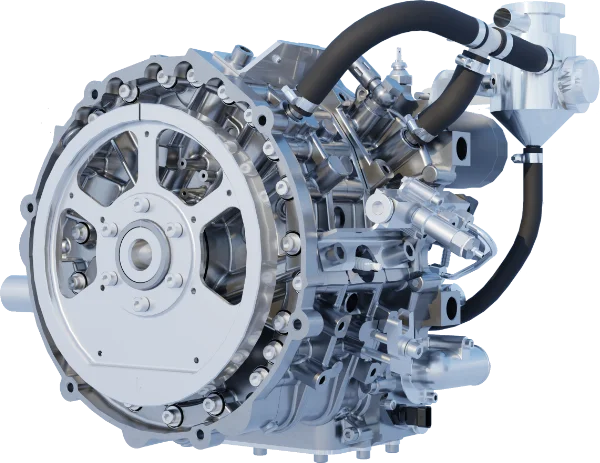

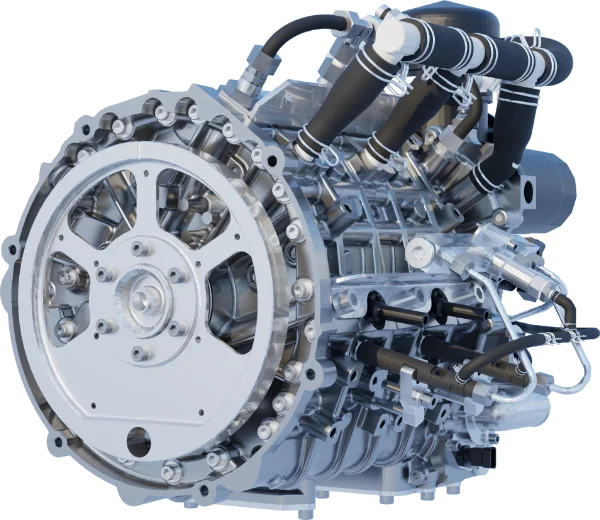

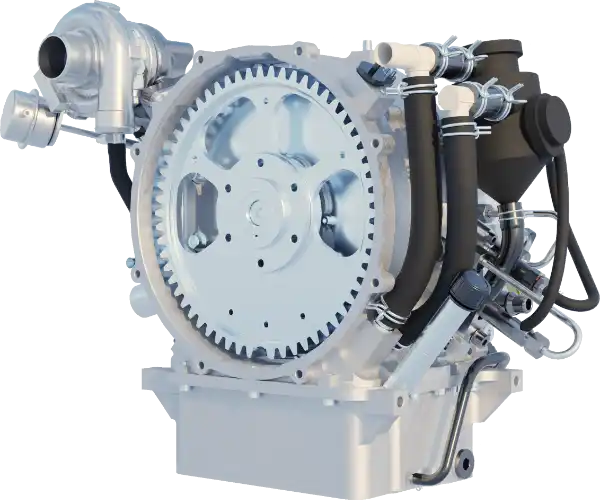

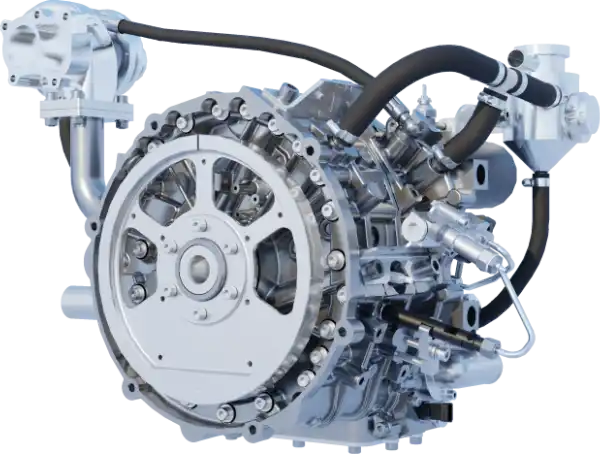

Our rotary engines are designed for powering generators and can run on almost any fuel, including diesel and hydrogen.

Our two engine series KKM350 with 350ccm respectively 500ccm displacement per rotor offers a wide range of configuration possibilities.

Our two engine series KKM350 with 350ccm respectively 500ccm displacement per rotor offers a wide range of configuration possibilities.

Built for high-performance use in small installation spaces

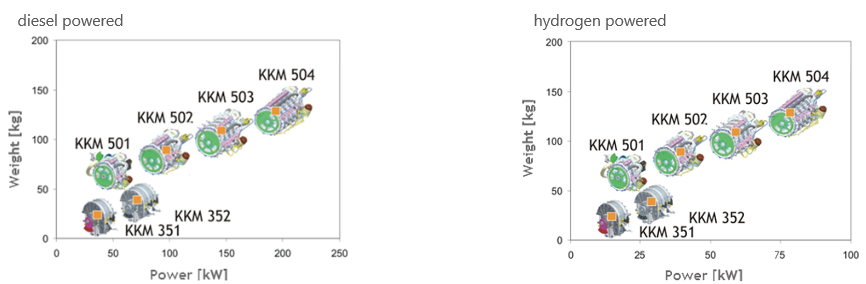

Running on diesel, our engines can generate/mechanical power from 15 kW to 140 kW, and as prototype KKM504d also up to 180 kWil the running on hydrogen, the power range reaches from 10 kW to 100 kW. Their small and almost cylindrical shape makes our engines ideal for powering generator sets and range extender systems, in stationary and mobile applications, on land and water and in the air.

Customizable to your application

We offer individual configurations of the engines for your applications. The electronic motor control unit (ECU) is manufactured and programmed by us. This enables you to adapt our motors to your system in line with your application.

You need support for the integration into your system? We support you in planning and installation!

You need support for the integration into your system? We support you in planning and installation!

Power-to-Weight Ratios of WST Engine Series KKM350 and KKM500

Characteristics of WST engines

- Reliable

- Very good performance- to-weight ratio

- low vibration

- multi-fuel

- Modular design

- WST's own ECU (hardware and software)

- Proprietary sealing and lubrication system

- Improved efficiency and reduced emissions due to proprietary injection and ignition technology

- Diesel

- JetA & other heavy fuels

- Gasoline

- LNG

- H2

- Methanole

- Ammonia

- Biogas

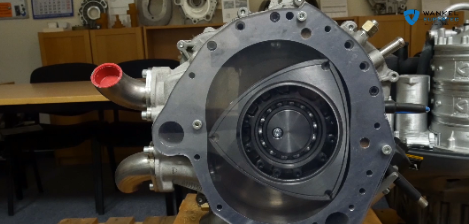

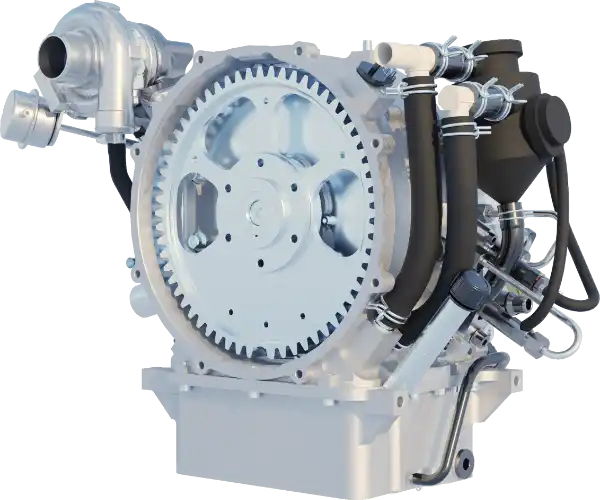

KKM351

Diesel-powered Rotary Engines KKM 350d

15 – 50 kW at 3,000 – 5,000RPM

- High power to weight ratio

- Low on vibrations

- Long life-expectancy

- Easy maintenance

- Good cost effectiveness

- Compact design

- Low production costs

- Turbocharged

- Single-rotor and double rotor

Above: KKM351d with 25kW permanent power

Specifications

- All engines with

- turbo charger

- intercooler

- high-pressure fuel injection

- Number of rotors

- Chamber volume

- Peak engine speed

- Weight base engine

- Weight incl. starter, alternator,

- turbo charger, intercooler, fuel

- injection, blowby, wiring

- harness, ECU

- -

- ccm

- min-1

- kg

- -

- -

- -

- kg

- KKM 351d

- 1

- 350

- 5,000

- 25

- -

- -

- -

- 41

- KKM 352d

- 2

- 2x350

- 5,000

- 34

- -

- -

- -

- 57

- Performance

- @ 3,000RPM

- @ 5,000RPM

- Spec. Fuel consumption

- @ 3,000RPM / 5,000RPM

- kW / Nm

- kW / Nm

- g/kWh

- -

- KKM 351d

- 14 / 44

- 25 / 48

- 290 / 310

- -

- KKM 352d

- 28 / 89

- 50 / 95

- 285 / 305

- -

- Performance specification net, before deductions for chargers

- Best fuel consumption for Diesel-fuel with density 0,835 kg/dm3 at 15°C

- Prototype

- Prototype

- Prototype

- Prototype

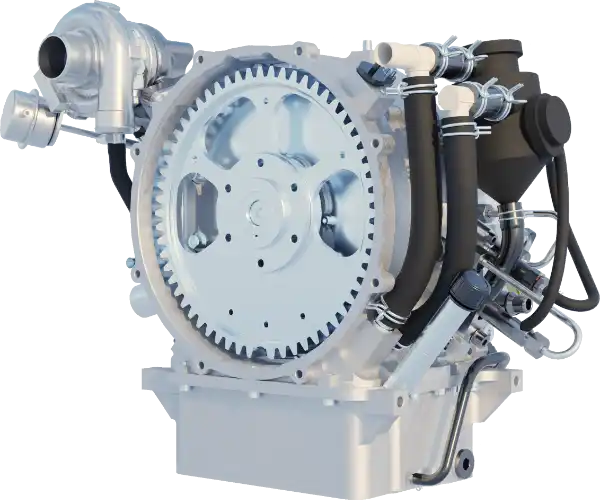

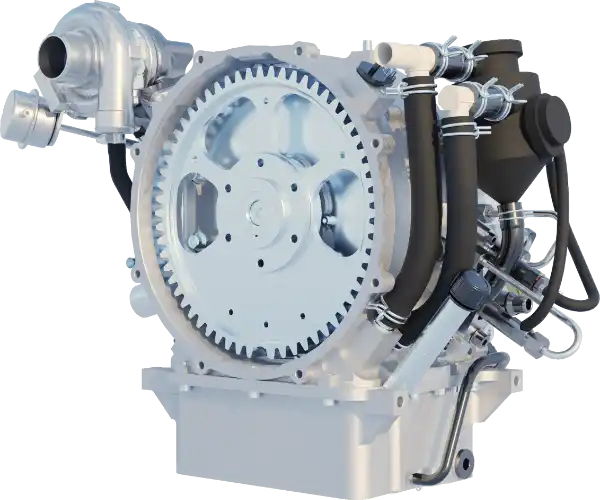

KKM352

Diesel-powered Rotary Engines KKM 350d

15 – 50 kW at 3,000 – 5,000RPM

- High power to weight ratio

- Low on vibrations

- Long life-expectancy

- Easy maintenance

- Good cost effectiveness

- Compact design

- Low production costs

- Turbocharged

- Single-rotor and double rotor

Above: KKM351d with 25kW permanent power

Specifications

- All engines with

- turbo charger

- intercooler

- high-pressure fuel injection

- Number of rotors

- Chamber volume

- Peak engine speed

- Weight base engine

- Weight incl. starter, alternator,

- turbo charger, intercooler, fuel

- injection, blowby, wiring

- harness, ECU

- -

- ccm

- min-1

- kg

- -

- -

- -

- kg

- KKM 351d

- 1

- 350

- 5,000

- 25

- -

- -

- -

- 41

- KKM 352d

- 2

- 2x350

- 5,000

- 34

- -

- -

- -

- 57

- Performance

- @ 3,000RPM

- @ 5,000RPM

- Spec. Fuel consumption

- @ 3,000RPM / 5,000RPM

- kW / Nm

- kW / Nm

- g/kWh

- -

- KKM 351d

- 14 / 44

- 25 / 48

- 290 / 310

- -

- KKM 352d

- 28 / 89

- 50 / 95

- 285 / 305

- -

- Performance specification net, before deductions for chargers

- Best fuel consumption for Diesel-fuel with density 0,835 kg/dm3 at 15°C

- Prototype

- Prototype

- Prototype

- Prototype

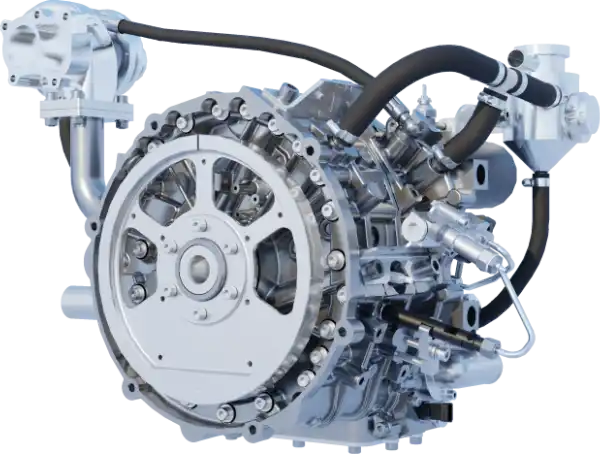

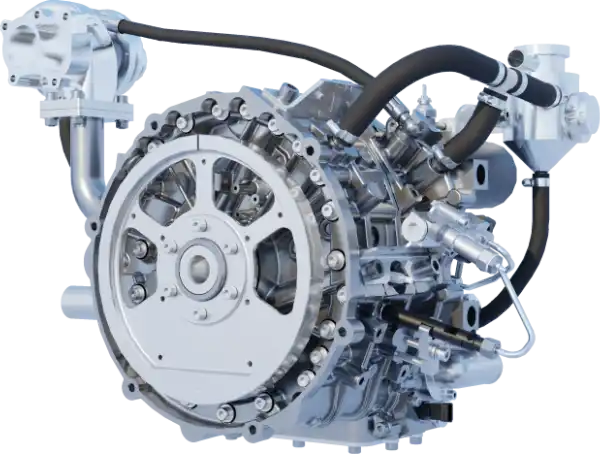

KKM501

Diesel-powered Rotary Engines KKM 500d

22 – 160 kW at 3,000 – 5,000RPM

- High power to weight ratio

- Low on vibrations

- Long life-expectancy

- Easy maintenance

- Good cost effectiveness

- Compact design

- Low production costs

- Turbocharged

- From single-rotor up to 4 rotors

Specifications

- All engines with

- turbo charger

- intercooler

- high-pressure fuel injection

Above: KKM503d with 66kW to 120kW

- Number of rotors

- Chambervolume

- Peak engine speed

- Weight base engine

- Weight incl. starter, alternator,

- turbo charger, intercooler, fuel

- injection, blowby, wiring

- harness, ECU

- -

- ccm

- min-1

- kg

- -

- -

- -

- kg

- KKM 501d

- 1

- 508

- 5,000

- 46

- -

- -

- -

- 70

- KKM 502d

- 2

- 2x508

- 5,000

- 63

- -

- -

- -

- 96

- KKM 502d

- 3

- 3x508

- 5,000

- 85

- -

- -

- -

- 123

- KKM 504d

- 4

- 4x508

- 5,000

- 105

- -

- -

- -

- 162

- Performance

- @ 3,000RPM

- @ 5,000RPM

- Spec. Fuel consumption

- @ 3,000RPM / 5,000RPM

- kW / Nm

- kW / Nm

- g/kWh

- -

- KKM 501d

- 22 / 70

- 45 / 71

- 285 / 305

- -

- KKM 502d

- 44 / 140

- 80 / 127

- 280 / 300

- -

- KKM 503d

- 66 / 210

- 120 / 190

- 275 / 295

- -

- KKM 352d

- 88 / 280

- 160 / 254

- 270 / 290

- -

- Performance specification net, before deductions for chargers

- Best fuel consumption for Diesel-fuel with density 0,835 kg/dm3 at 15°C

- KKM 504d under development

- Prototype

- Prototype

- Prototype

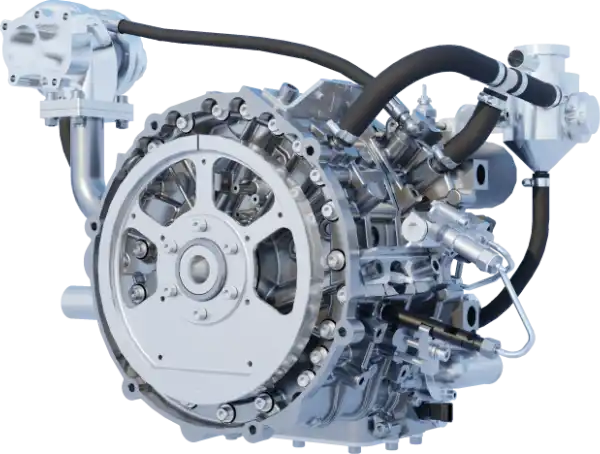

KKM502

Diesel-powered Rotary Engines KKM 500d

22 – 160 kW at 3,000 – 5,000RPM

- High power to weight ratio

- Low on vibrations

- Long life-expectancy

- Easy maintenance

- Good cost effectiveness

- Compact design

- Low production costs

- Turbocharged

- From single-rotor up to 4 rotors

Specifications

- All engines with

- turbo charger

- intercooler

- high-pressure fuel injection

Above: KKM503d with 66kW to 120kW

- Number of rotors

- Chambervolume

- Peak engine speed

- Weight base engine

- Weight incl. starter, alternator,

- turbo charger, intercooler, fuel

- injection, blowby, wiring

- harness, ECU

- -

- ccm

- min-1

- kg

- -

- -

- -

- kg

- KKM 501d

- 1

- 508

- 5,000

- 46

- -

- -

- -

- 70

- KKM 502d

- 2

- 2x508

- 5,000

- 63

- -

- -

- -

- 96

- KKM 502d

- 3

- 3x508

- 5,000

- 85

- -

- -

- -

- 123

- KKM 504d

- 4

- 4x508

- 5,000

- 105

- -

- -

- -

- 162

- Performance

- @ 3,000RPM

- @ 5,000RPM

- Spec. Fuel consumption

- @ 3,000RPM / 5,000RPM

- kW / Nm

- kW / Nm

- g/kWh

- -

- KKM 501d

- 22 / 70

- 45 / 71

- 285 / 305

- -

- KKM 502d

- 44 / 140

- 80 / 127

- 280 / 300

- -

- KKM 503d

- 66 / 210

- 120 / 190

- 275 / 295

- -

- KKM 352d

- 88 / 280

- 160 / 254

- 270 / 290

- -

- Performance specification net, before deductions for chargers

- Best fuel consumption for Diesel-fuel with density 0,835 kg/dm3 at 15°C

- KKM 504d under development

- Prototype

- Prototype

- Prototype

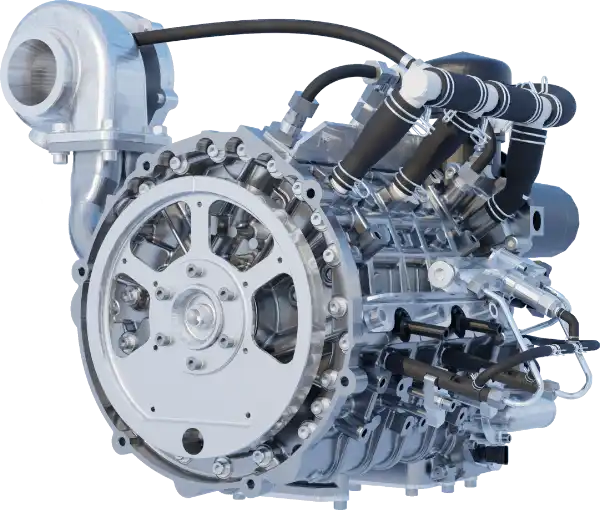

KKM503

Diesel-powered Rotary Engines KKM 500d

22 – 160 kW at 3,000 – 5,000RPM

- High power to weight ratio

- Low on vibrations

- Long life-expectancy

- Easy maintenance

- Good cost effectiveness

- Compact design

- Low production costs

- Turbocharged

- From single-rotor up to 4 rotors

Specifications

- All engines with

- turbo charger

- intercooler

- high-pressure fuel injection

Above: KKM503d with 66kW to 120kW

- Number of rotors

- Chambervolume

- Peak engine speed

- Weight base engine

- Weight incl. starter, alternator,

- turbo charger, intercooler, fuel

- injection, blowby, wiring

- harness, ECU

- -

- ccm

- min-1

- kg

- -

- -

- -

- kg

- KKM 501d

- 1

- 508

- 5,000

- 46

- -

- -

- -

- 70

- KKM 502d

- 2

- 2x508

- 5,000

- 63

- -

- -

- -

- 96

- KKM 502d

- 3

- 3x508

- 5,000

- 85

- -

- -

- -

- 123

- KKM 504d

- 4

- 4x508

- 5,000

- 105

- -

- -

- -

- 162

- Performance

- @ 3,000RPM

- @ 5,000RPM

- Spec. Fuel consumption

- @ 3,000RPM / 5,000RPM

- kW / Nm

- kW / Nm

- g/kWh

- -

- KKM 501d

- 22 / 70

- 45 / 71

- 285 / 305

- -

- KKM 502d

- 44 / 140

- 80 / 127

- 280 / 300

- -

- KKM 503d

- 66 / 210

- 120 / 190

- 275 / 295

- -

- KKM 352d

- 88 / 280

- 160 / 254

- 270 / 290

- -

- Performance specification net, before deductions for chargers

- Best fuel consumption for Diesel-fuel with density 0,835 kg/dm3 at 15°C

- KKM 504d under development

- Prototype

- Prototype

- Prototype

- Prototype

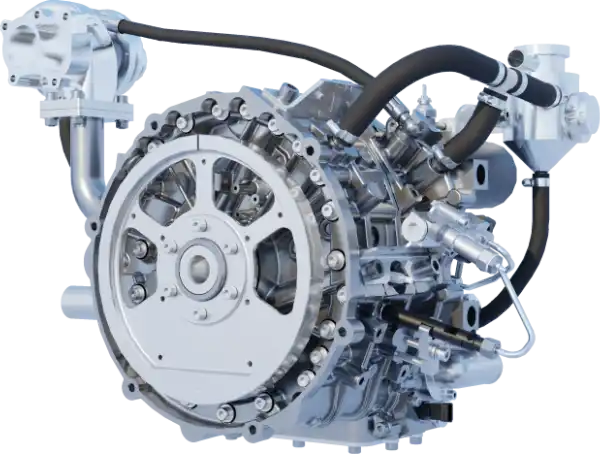

KKM504

Diesel-powered Rotary Engines KKM 500d

22 – 160 kW at 3,000 – 5,000RPM

- High power to weight ratio

- Low on vibrations

- Long life-expectancy

- Easy maintenance

- Good cost effectiveness

- Compact design

- Low production costs

- Turbocharged

- From single-rotor up to 4 rotors

Specifications

- All engines with

- turbo charger

- intercooler

- high-pressure fuel injection

Above: KKM503d with 66kW to 120kW

- Number of rotors

- Chambervolume

- Peak engine speed

- Weight base engine

- Weight incl. starter, alternator,

- turbo charger, intercooler, fuel

- injection, blowby, wiring

- harness, ECU

- -

- ccm

- min-1

- kg

- -

- -

- -

- kg

- KKM 501d

- 1

- 508

- 5,000

- 46

- -

- -

- -

- 70

- KKM 502d

- 2

- 2x508

- 5,000

- 63

- -

- -

- -

- 96

- KKM 502d

- 3

- 3x508

- 5,000

- 85

- -

- -

- -

- 123

- KKM 504d

- 4

- 4x508

- 5,000

- 105

- -

- -

- -

- 162

- Performance

- @ 3,000RPM

- @ 5,000RPM

- Spec. Fuel consumption

- @ 3,000RPM / 5,000RPM

- kW / Nm

- kW / Nm

- g/kWh

- -

- KKM 501d

- 22 / 70

- 45 / 71

- 285 / 305

- -

- KKM 502d

- 44 / 140

- 80 / 127

- 280 / 300

- -

- KKM 503d

- 66 / 210

- 120 / 190

- 275 / 295

- -

- KKM 352d

- 88 / 280

- 160 / 254

- 270 / 290

- -

- Performance specification net, before deductions for chargers

- Best fuel consumption for Diesel-fuel with density 0,835 kg/dm3 at 15°C

- KKM 504d under development

- Prototype

- Prototype

- Prototype

- Prototype

- Prototype

- Prototype

- Prototype

- Prototype

Hydrogen-powered engines

Series KKM 500H2

Diesel-powered engines

Series KKM 500D

KKM 502d

1016 ccm | TDI | 90 kW | 5000 rpm | diesel, jet fuel | 572 x 663 x 497 mm | 82 kg

KKM 503d

1016 ccm | TDI | 130 kW | 5000 rpm | diesel, jet fuel | 572 x 663 x 497 mm | 82 kg

KKM 504d

1016 ccm | TDI | 160 kW | 5000 rpm | diesel, jet fuel | 572 x 663 x 497 mm | 82 kg

For information on further configuration, including for mixed-fuel operation, please contact us

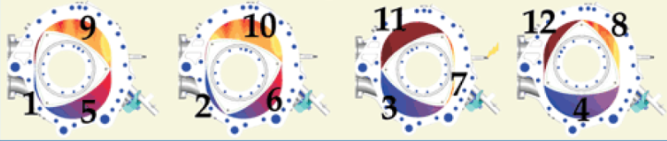

Functional principle and multi-fuel capability

-

Four-stroke principle:

- 1st intake ( 1, 2, 3, 4 )

- 2nd compression ( 5, 6, 7 )

- 3rd expansion ( 8, 9, 10 )

- 4th exhaust ( 11, 12 )

fossil

diesel

gasoline

kerosine

natural gas

LPG

renewable

bio-diesel

ethanole

methanole

hydrogen

biogas

Diesel injection via high-pressure common rail in the expansion area, combined with spark ignition Injection of hydrogen in the compression area with an injection pressure of approx. 10 bar