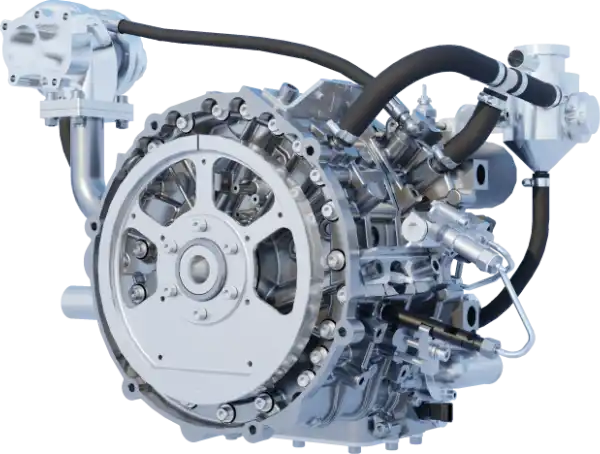

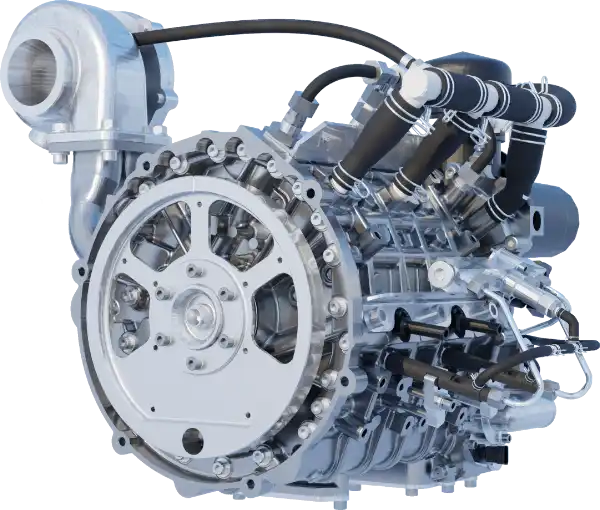

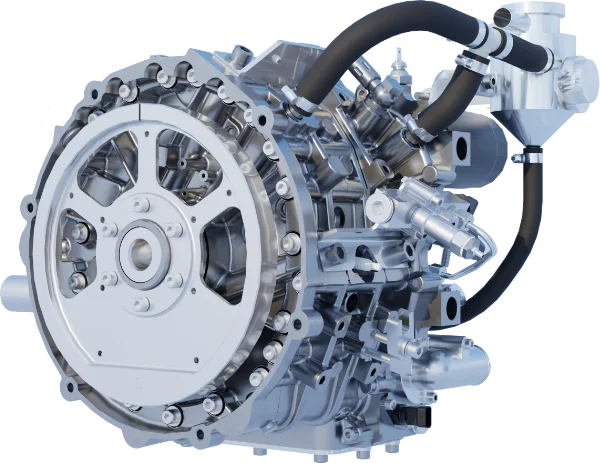

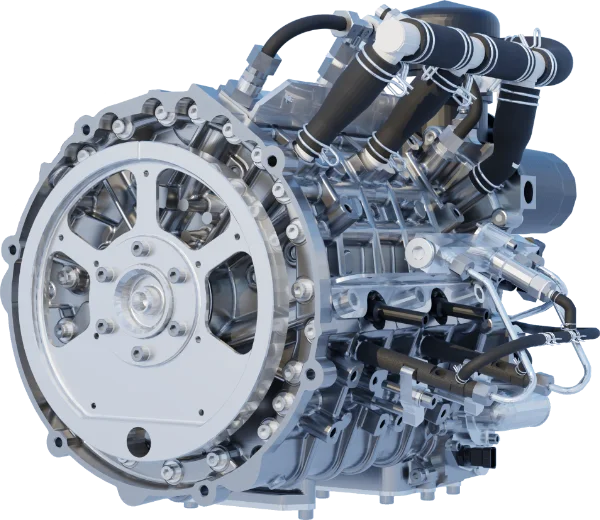

Built for high performance use in small installation spaces.

Our motors allow mechanical power from 15 kW - 90 kW. With an overall height of less than 50 cm. This makes them ideal for generator sets and the upgrading of auxiliary power units, auxiliary power generators and power generators. On land and on water.

Our engines are optimized for diesel and hydrogen. This makes us the world's only supplier of diesel-powered Wankel engines and Europe's only supplier of hydrogen combustion engines.

Our engines are optimized for diesel and hydrogen. This makes us the world's only supplier of diesel-powered Wankel engines and Europe's only supplier of hydrogen combustion engines.

Hydrogen combustion engines as reasonable alternative to fuel cells

The hydrogen engines are currently being optimized. We have already delivered hydrogen engines since 2019 and are constantly working on their efficiency.

The hydrogen engines we offer represent the current state of development and have not yet reached their best point. Together with universities, we are continuously working on material and component research to achieve higher efficiency.

The hydrogen engines we offer represent the current state of development and have not yet reached their best point. Together with universities, we are continuously working on material and component research to achieve higher efficiency.

Customizable to your application

We offer individual configuration of the engines for your applications. The electronic motor control unit (ECU) is manufactured and programmed by us. This enables you to adapt our motors to your system in line with your application.

You need support for the integration into your system? We support you in planning and installation!

You need support for the integration into your system? We support you in planning and installation!